ATLAS HO SCALE STANDARD SLOTCAR CHASSIS

ATLAS HO SCALE STANDARD SLOTCAR CHASSIS

by Joe Bodnarchuk - MisterAtlas

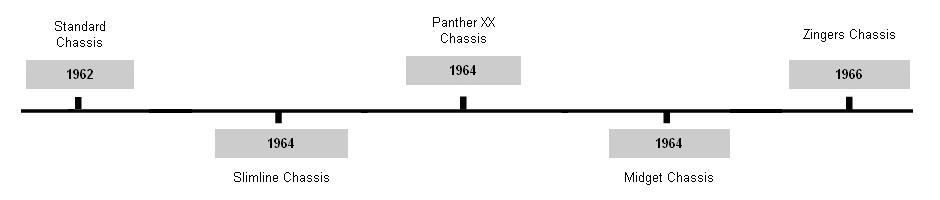

There are several variations of slot car chassis that were manufactured and used from 1962 to 1969.

The first chassis ever used in production is what I call the STANDARD¹ chassis.

This STANDARD chassis was utilized in the early issue (PB) PAINTED BUMPER², as well as, the early versions of the (CB) CHROME BUMPER³ Atlas slotcars.

¹²³I am pleased to say that these terms have been part of the commonplace slotcar lexicon ever since I coined them several decades ago.

Atlas HO Scale Slot Car Chassis Marketplace Introduction Timeline

Standard Chassis -

Slimline Chassis -

Panther XX Chassis -

Midget Chassis -

ZINGERS Chassis

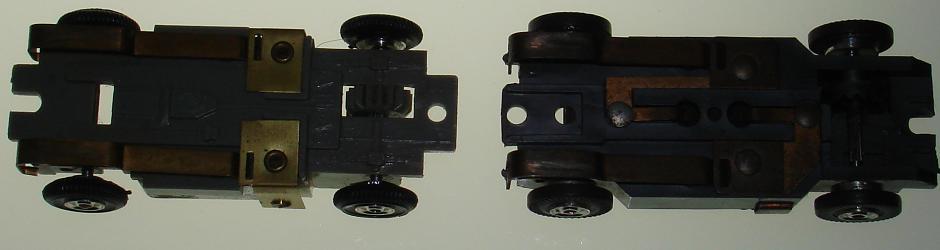

ATLAS PAINTED BUMPER VS CHROME BUMPER

As can be witnessed in the above examples, the STANDARD

slotcar

chassis

unit in this

slot car

was designed to permit a truer scale reproduction of

slot cars of this size.

With proper care and maintenance, your

Atlas

slotcars

should give you countless hours of satisfactory running.

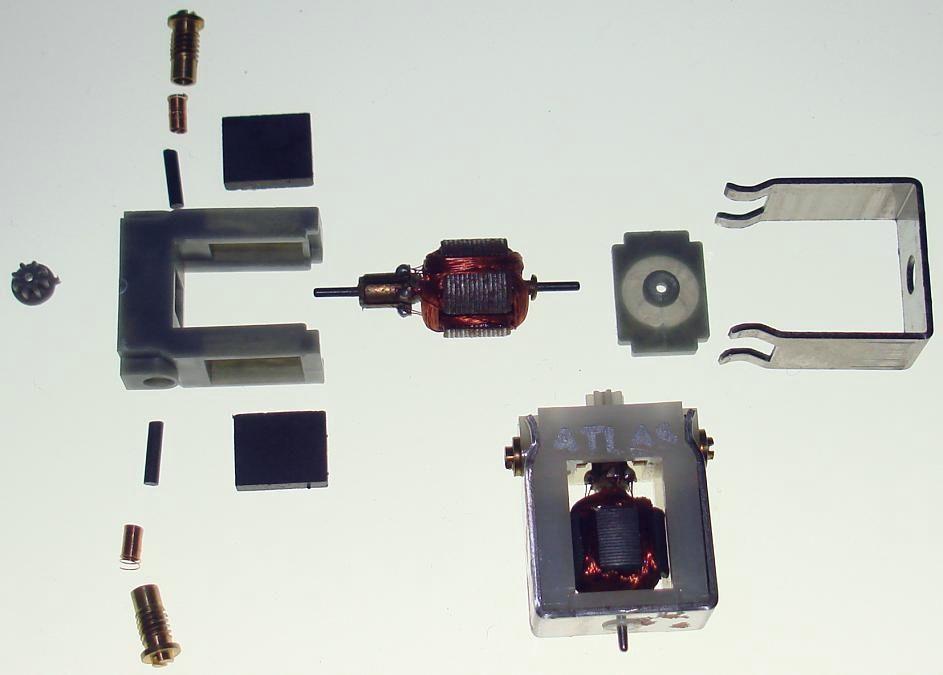

Early Atlas slotcar STANDARD chassis operate by a 5 pole 12 Volt D.C. motor geared to the rear axle.

Chassis that have been in storage for decades should be relubricated and test driven to assure smooth operation.

Each slot car should be operated at full speed to fully seat carbon brushes and break in the motor bearings before top performance can be expected.

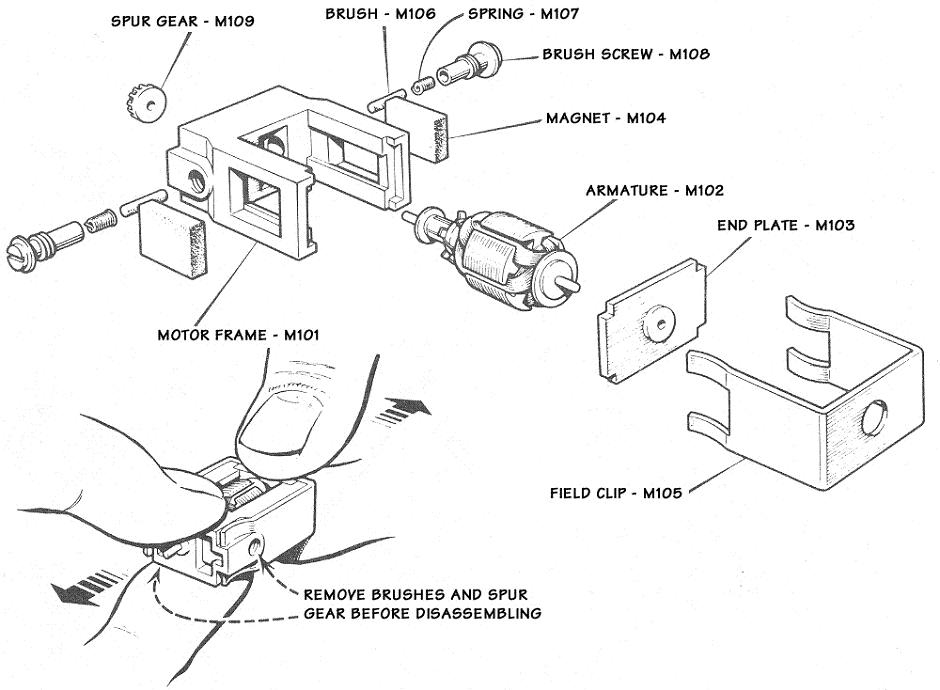

To replace worn brushes, unscrew the Brush Screw part #M108 and pull on the end of the Motor Frame part #M107.

The Brush will pull out of the Brush Spring for an easy replacement.

The Brush Spring part #M107 has a closed end that goes into the end hole of the Brush Screw.

Push a new Brush into the Brush Spring and screw the unit back into the Motor Frame.

It is always best to replace BOTH brushes at same time.

Your motor will need a break in track run to fully seat the new brushes before top performance can be expected.

If it becomes necessary to take the motor apart, remove the Brushes first and the Spur Gear next.

Then firmly grasp the base of the Motor Frame between 2 fingers and hold the End Plate and Field Clip with other hand.

Pull firmly to separate these parts as demonstrated in the following schematic.

ILLUSTRATED EXPLODED MOTOR SCHEMATIC

ILLUSTRATED EXPLODED MOTOR VIEW

CORRECT PROCEDURE FOR ASSEMBLING MOTOR

- Hold Motor Frame M101 in left hand, insert Commutator end of Armature part #M102 into bearing hole.

- Place End Plate part #M103 on either end of ARMATURE and push into open end of MOTOR FRAME.

- Place MAGNETS part #M104 into opening at each side of MOTOR FRAME, being careful that they are pulling toward each other.

- Spread Field Clip part #M105 to go over sides of MOTOR FRAME and slide together until indents clip into place.

Make sure end bearing of END PLATE goes into hole of Field Plate

- Insert Brush part #M106 into Spring part #M107 and then into Brush Screw part #M108.

This unit is then screwed into Motor Frame. Do not force screw as you might strip the threads.

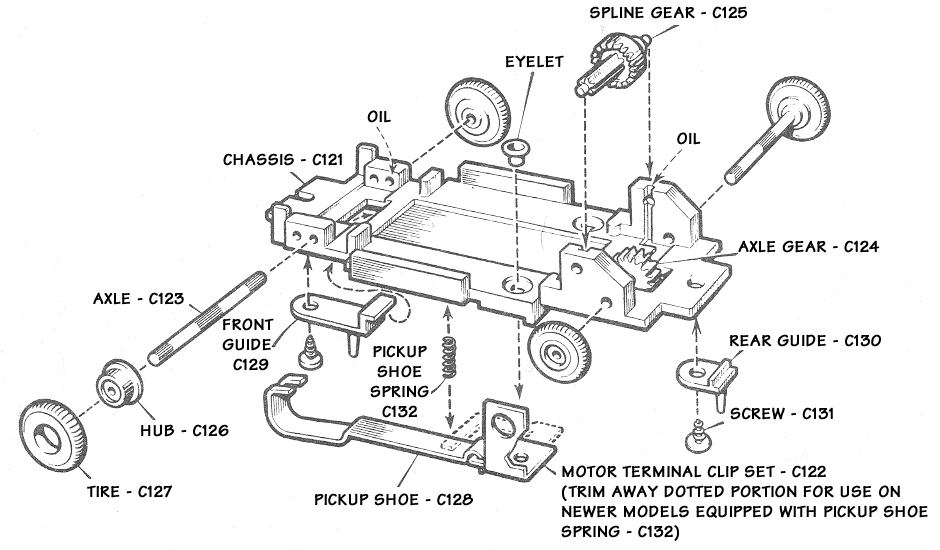

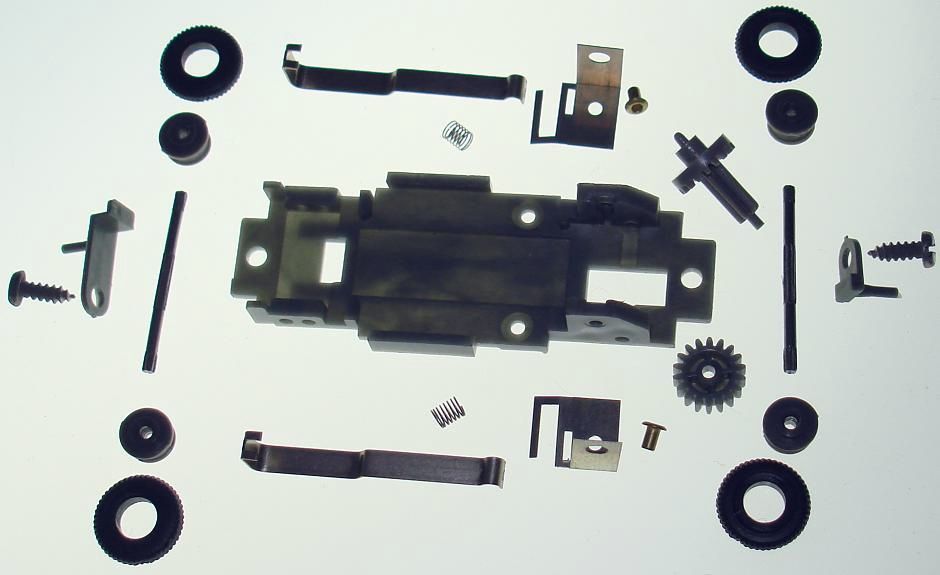

ILLUSTRATED EXPLODED CHASSIS SCHEMATIC

ILLUSTRATED EXPLODED CHASSIS VIEW

A drop of oil is needed on the inside shaft bearing on the front of chassis and in oil channels as shown in exploded chassis assembly drawing will give smooth operation.

HINT: Use dab of Petroleum Jelly - Vaseline® - on end of motor shaft bearings. Do NOT use oil on motor shaft.

Keep slot car track roadway clean by wiping with dry soft cloth. Static electricity will attract lint to axles and gears causing improper performance and possible damage.

HINT: For best results do NOT run any slot car set directly on carpet.

ATLAS AURORA CHASSIS COMPARISON

Atlas produced fewer slotcars than Aurora did.

I do not know exact Atlas production numbers so I can only speculate, based upon my 4+ decades of collecting experience, that much fewer than ten thousand complete chassis - 10K chassis - 10,000 chassis still exist.

Unless a major find is made, these numbers will not fluctuate more than a few percentage points in either direction.

This fact alone makes most Atlas chassis uncommon at best and quite scarce at times.

I do know for a fact that tens of millions of Aurora chassis were produced and that almost three million were still available well into the 1990s.

Most hobbyists are familiar with the operational functionality of the Aurora Model Motoring Thunderjet 500 Chassis - called TJET for short.

Let me assure you, from personal experience, that each stock Atlas chassis meets or exceeds the stock TJET chassis on many different levels.

Would you like to purchase this chassis or individual replacement parts?

We have many HO Scale Slot Car Racing Motor & Chassis Parts For Sale

Atlas Standard Motor Parts For Sale:

m101 motor frame

m102 armature

m103 end plate

m104 magnet

m105 field clip

m106 brush

m107 spring

m108 brush screw

m109 spur gear

Atlas Standard Chassis Parts For Sale:

c121 chassis

c122 motor terminal clip set

c123 axle

c124 axle gear

c125 spline gear

c126 hub

c127 tire

c128 pickup shoe

c129 front guide

c130 rear guide

c131 screw

c132 pickup shoe springs

| MisterConey.com | MrConey.com | Slot Car Digest Motoring & Racing Slotcar Magazine | Slot Car Museum |